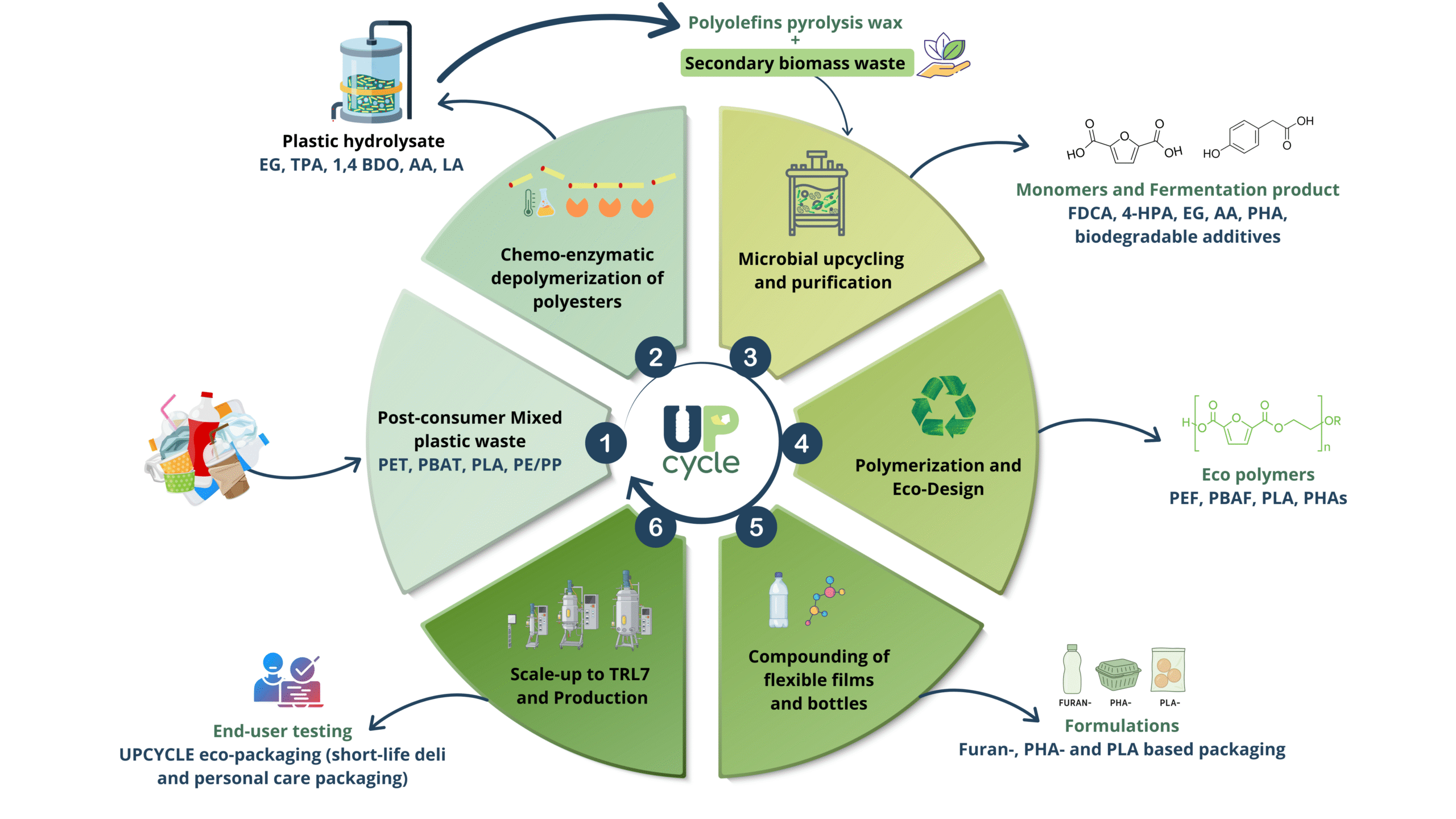

UPCYCLE aims to create new circular value chains that turn today’s non-recyclable plastic waste into highly recyclable and non-persistent packaging materials, ensuring they do not remain in the environment for centuries.

Building on the H2020 UPLIFT project, UPCYCLE addresses scalability hotspots to reach economic viability by scaling a plastic biorefinery and ecopolymers strategy guided by SSbD, AI-powered fast-track innovation, versatile biorefinery processes, and smart polymerisation / formulation.

Demonstrating the safe and sustainable design of biodegradable polymer materials for packaging applications.

Eco-design and smart formulations using bio-based additives and building-blocks.

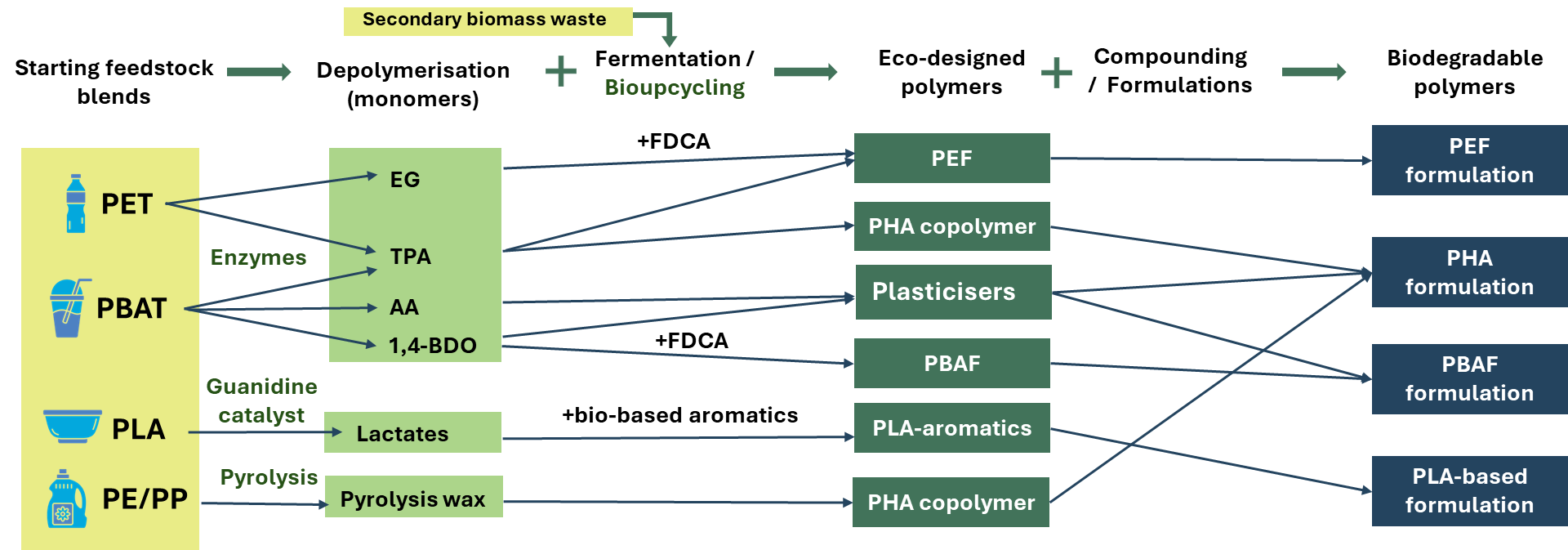

Demonstrating chemo-enzymatic depolymerisation of post-consumer mixed plastic packaging waste streams as novel feedstock.

Demonstrating bio-upcycling of plastic waste to produce biodegradable and recyclable building blocks.

Ensuring the market uptake of UPCYCLE’s novel processes and products for maximised impact.

Vegetable flexible packaging (salads): overcoming PE recyclability issues and food-residue contamination via enzymatically recyclable and compostable alternatives.

Short-lifetime deli packaging (cheese): replacing nearly non-recyclable multilayer PE/PA with bio-based recyclable / compostable mono-materials.

Beverage bottles (e.g., liquid kefir): renewable, recyclable mono-material formulations compatible with mechanical and/or chemo-enzymatic recycling, supporting EPR strategies.

Personal care bottles (shampoo): robust packaging designed for compatibility with mechanical and chemo-enzymatic recycling, increasing recycled / biodegradable content.

Novel eco-designed polymer materials (PHA-, PLA-, and furan-based polymers) that exhibit the desired technical performance while providing environmental benefits and low carbon footprint

Develop sustainable additives and catalysts to support the production of bio-degradable polymers.

UPCYCLE will have developed at least four use-case biodegradable and recyclable polymer systems, demonstrated at TRL7, for flexible film packaging (salads, cheese) and bottles (liquid kefir, shampoo).

Next generation of biodegradable polymer materials, which will also be recyclable materials

Switch from PP, PE, and PET to bio-degradable materials with 30% reduced GHG emissions.

Packaging industry will apply business model of circularity-by-design and sustainable end-of-life (EoL) solutions.

Reduction in landfill waste volume of packaging materials.

Reduce the plastic pollution of the oceans / environment.

Cascade approach for PET/PBAT enzymatic hydrolysis and monomer recovery; PLA depolymerisation via non-toxic guanidine metal catalysts (including continuous extrusion); pyrolysis of remaining PE/PP to wax for fermentation.

Increase titres and yields for PHB/mcl-PHA from PET/PBAT hydrolysates and from PE pyrolysis wax; produce biobased plasticisers (e.g., levulinic acid derivatives) and FDCA.

Smart copolymerisation/blending of PHA-, PLA-, and furan-based systems using bio-based degradable additives (e.g., HPAA-based approaches); continuous reactive extrusion (REX) explored for scalable processing.

Select most promising routes and scale batches to 10-25 kg (materials) and up to 25 kg per batch (depolymerisation), preparing for TRL7 demonstrations.

Addressing reactor design, process control, and industrial integration with a holistic up/downstream approach.

Compounding/blending and transformation into films (twin screw/cast extrusion) and bottles (blow moulding); testing materials at 100-200 kg scale with end-user validation.

Virtual replicas for real-time simulation and optimisation across depolymerisation, fermentation, and polyester synthesis; sensitivity analysis and cost modelling (TEA, CAPEX/OPEX) to guide efficiency and MSP reduction.